Definition of open loop. Using open-loop extraction exposes the final concentrate product to the.

Difference Between Open Loop Closed Loop System With Comparison Chart Circuit Globe

The pcm can only correct so much.

. This month we will explore the new fuel system definitions that are present on many of todays vehicles. The system remains in open-loop until the following three conditions are met. To keep car running correctly when engine warmed up and oxygen sensor heater came on and activated the PCM Should switch to the.

For example making butane hash oil BHO in an open-extraction system involves placing the plant material into an open-ended tube and running the butane through the tube and across the plant material to extract the concentrated oil of the plant fiber. Under heavy acceleration the system will generally go open loop some vehicles may remain in closed loop. Noun an automatic control system in which an operation process or mechanism is regulated by feedback.

When the engine is first started the system goes into open loop operation. Answer 1 of 2. Open loop can be caused by various sensors going bad but it has a corresponding code when that happens.

Consider the common unitary feedback loop. Closed-loop control means that there is some kind of position information that is fed back to the motion controller of a system and that is used in the positioning process. It typically refers to an open-tube butane run.

Techopedia Explains Closed-Loop Control System. Well begin our discussion by looking at each one on an individual basis. A control system for an operation or process in which there is no self-correcting action as there is in a closed loop.

Open-loop feedforward control and closed loop feedback control. In the closed-loop system the desired output depends on their input. Usually open loop is used on initial start and during warmup until the 02 sensor reaches its operating temperature and produces a signal and the engine also reaches its operating temp at which point the switch to closed loop takes place.

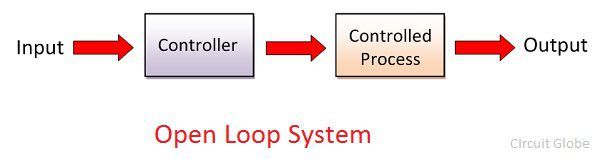

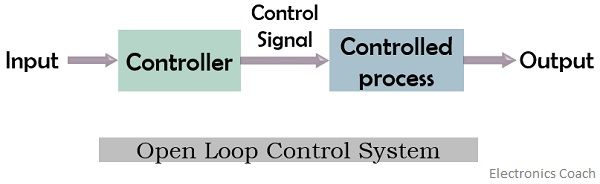

In open-loop control the control action from the controller is independent of the process output or controlled process variable. In open loop mode the engine doesnt listen to nobody it just runs off a set of instructions based on where the throttle is at where the revs are and so on. The open-loop control system block diagram is shown below.

In this session we are going to discuss about Open Loop Closed Loop systems. The first definition is open loop Simply stated the oxygen sensor is not being used for feedback control. Fundamentally there are two types of control loop.

What does open-loop mean. The open loop system is more stable as compared to a closed loop system. However this obtained output cannot be considered using this system for additional reference input.

If the o2s are sticking leanrich it doesnt mean they are bad. Here the word stable means the output of the system remains constant even after the disturbances. In the feedback system C is the controller.

The phrase closed-loop system is often paired with circular economy which is an industrial system that is restorative and regenerative by intention or design to use the World Economic Forums definitionIts helpful to think of literal loops or. A control system that does not have a feedback loop and thus is not self-correcting. Otherwise there is no route for electric current to flow from the probe to probe.

Closed-loop systems have many advantages over open-loop systems. P is the process. Open loop definition a control system in which an input alters the output but the output has no feedback loop and therefore no effect on the input.

The open loop system means the output of the system is free from their input. Closed loop control systems are feedback control systems. A sensor closes the loop.

4 Dec 23 2010. In general open-loop control in motion systems means that there is no position feedback of a moving object. Xeryon specializes in ultrasonic piezo-motors but the principles you read below apply to all kind of.

Meaning to say there is no continuity. In a nutshell closed loop is where the engine operates with a feedback loop. It is a closed-loop system used explicitly or implicitly in lots of physical biological economical and other systems.

The difference between the open-loop control system and the closed-loop control system is that the open-loop control system only takes in the input and produces the output. In open loop the ECM calculates the AirFuel ratio based on inputs from the coolant and MAF sensors. A good example of this is a central heating boiler controlled only by a timer so that heat is applied for a constant time regardless.

It could mean they are doing there job and seeing a leanrich condition from something. There are two types of control systems namely Open Loop Closed Loop system Open loop control systems are non-feedback control systems. In the following system it includes two blocks like controller as.

In the following diagram the input can be given to the control system so that the required output can be obtained. The primary advantage of a closed-loop feedback control system is its ability to reduce a systems sensitivity to external disturbances for example opening of the dryer door giving the system a more robust control as any changes in the feedback signal will result in. With this in mind it requires initial event-driven management to generate the model whereas the closed-loop control system continually takes the output to.

Up to 25 cash back The open loop mean the car is still cold basically when the engine is still cold and the Heated Oxygen sensor are heating up the PCM get it Air fuel ratio from the ECT sensor map sensor maf sensor etc. 5 of the Most Reliable All-Purpose Multimeters Testing Continuity the screen will show 1 or OL open loop is the test is not detected.

Open Loop Closed Loop Control System And Their Differences

What Is An Open Loop System Examples Advantages Disadvantages

What Is Open Loop Control System Definition Open Loop System Advanatges Disadvantages And Applications Electronics Coach

0 Comments